A project can be big or small; anything from changing a light bulb to building a fighter jet. As the complexity of a project increases and the duration extends to weeks and months, it’s helpful to decompose the overall program into smaller steps. A work breakdown structure is a project management tool for exactly that purpose.

Thinking of a project as one single entity is a recipe for disaster; you have to break things up into smaller chunks. But, human brains have limited working memory and can only keep track of a finite number of things at once.

You need to be smart about how you split up the pieces of your project so you stay efficient. Work breakdown structures (commonly abbreviated as WBS) apply a systematic approach to this. They make complex things more manageable.

As we jump into this topic, we’ll clarify what a WBS is, why it’s important, and how you can use it on your construction project to have the best outcome possible. And at the end of the article, we’ll share the WBS we’ve created specifically for shipping container home projects!

Work Breakdown Structure Overview

A WBS is a project management fundamental, useful for everyone from backyard hobbyists to professional project managers. While not particularly exciting, a WBS often forms the backbone upon which the schedule, budget, and other documents are built.

What is a Work Breakdown Structure

The basic formula for a WBS is to take the complete scope of a project, break it up into pieces, then organize them into a logical hierarchy. All the items at a lower level are needed to complete the item at the next highest level.

Using multiple smaller pieces allows each one to be defined, managed, and monitored. Before we go much further, an example WBS will probably be helpful.

As you can see, the bicycle is divided into assemblies and parts until everything is accounted for and just from looking at the words, you have a good idea of how everything goes together.

The hierarchical nature of a WBS means it is really just a certain type of taxonomy or classification. Think about the way we put every biological species into progressively larger groups like genus, family, order, etc. Or the way military units are divided the same way into platoons, companies, and battalions.

It’s very likely that you’ve been informally making WBS’s all along and just didn’t have a name for it. Clearly then, what we’re sharing here isn’t earth-shattering knowledge. Rather, it’s a way to systematically do what you were likely already doing in order to make your existing process better.

Importance of a Work Breakdown Structure

In many ways, a WBS is an intermediate piece of a larger process. By itself, a WBS is interesting but not necessarily all that useful. Instead, view it as a stepping stone.

Think about making a project schedule. How helpful would it be to have only a single line item inside it without any breakout for specific phases of work? Even something as simple as food recipe has multiple steps after all.

How about a cost estimate or budget? Wouldn’t it be much easier to break up a project into smaller pieces, estimate the costs of those, and then add them together instead of trying to come up with the cost of the entire project in one effort?

Or if you were getting ready to hire a subcontractor and wanted to know what exactly they would be doing so you didn’t accidentally hire someone else to do part of the same work by mistake?

Having a WBS can help tremendously with these types of problems and issues and provide benefits like:

- Accountability: It’s incredibly important to clearly delegate who has responsibility for what, but that can only be done if everyone is clear on the ‘what’. Even if you’re working by yourself, you can hold yourself accountable if you have to visually look at what you’re trying to do in writing.

- Risk Management: Ambiguity is the enemy of successful projects. Anytime there is a question of who is doing what, what has to get done first, or where on the project a particular material goes, there can be construction errors, time delays, or cost overruns. Having a WBS helps you managed and reduce project risk.

- Clarity: The simple act of making the WBS will force you to better understand the project and all its intricacies, which will only benefit you. If you can see it (written down), you can measure it. And as they say, what gets measured gets done. This applies across time, money, and even quality.

- Efficiency: Having a WBS in hand allows you to more holistically view your project. With that perspective, you can more easily see opportunities like buying similar materials in bulk, accomplishing similar types of work at the same time, etc.

Most lessons are born out of mistakes. Ideally, you can learn from the mistakes of others instead of making your own.

The project planning process exists specifically to minimize and ideally avoid mistakes, and creating a WBS is an integral part of that process. We’re confident that you’ll actively use a WBS as you create a budget/cost estimate and project schedule. But even if you don’t, the process of making a WBS will be helpful to guide your thinking in a logical manner.

There are plenty of maxims related to project planning. One popular version of the Seven P’s of Planning states: Proper Prior Planning Prevents Painfully Poor Performance (there are some other, less polite versions as well). Or a similar, shorter saying: If you fail to plan, you plan to fail.

No matter how you say it, the overall idea is the same. Making a concerted effort on the front-end of your project to think through resources, activities, and relationships will go far toward ensuring you finish the project as well as you start it. A WBS isn’t the only part of planning, or even the most important, but it is certainly a significant piece.

Principles of a Project Management WBS

Almost every type of work uses classifications, and project management is no different. A WBS is a tool that helps you breakdown and classify smaller pieces of a project.

A WBS is typically based on end products, decisions, or deliverables. Each smaller piece, as well as the overall project itself, actually creates or does something. Another way to think about it is by focusing on nouns instead of verbs: you want to be classifying outcomes, not the actions that cause them.

For instance, simply thinking about something, though important, would not be a good WBS task. Rather, the decision or document that’s a result of that thinking is what you should record in a WBS.

When choosing elements to include in a WBS, they need to be Mutually Exclusive and Collectively Exhaustive, or MECE:

-

- Mutually Exclusive: The WBS cannot have any overlap in scope between different elements, meaning the same items can’t be covered in multiple places.

- Collectively Exhaustive: Also known as the 100% Rule — The WBS must include all of the work of the project, and each ‘child’ level must include all of the work necessary to complete the ‘parent’ element one level up.

Specific to the area of Project Management is another WBS creation principle called the 8/80 rule. It states that any lowest level element should take somewhere between 8 and 80 hours to complete.

Shorter than that and it should be combined with other elements and possibly moved up a level to keep the WBS from getting large and unruly. Longer than that and the element should be further split into sub-elements to keep the WBS from being too high level.

Construction Work Breakdown Structure Frameworks

Up to this point, we’ve considered WBS’s as a part of all types of project management. But now, it’s time to dig a little deeper into how these tools apply to construction.

Construction management is a specific part of project management that is really its own area of study. There are organizing bodies, personal certifications, and specific procedures and terminology that just pertain to managing construction projects.

Given the sheer number of construction projects taking place each year and the billions of dollars spent, it’s no wonder that such specialization exists. Even the ISO has gotten involved, creating ISO 12006-2:2015 specifically to outline a framework of classification for construction projects. Yes, that’s the same ISO that sets the standards for the dimensions and requirements of containers.

Still, with all this attention, there are numerous ways to break construction projects up into smaller pieces. You could start by categorizing based on the created product, like walls, roof, or floor. Or you could categorize based on material, like wood, metal, or cement.

While you can certainly make up your own way of classifying your project tasks, there are thousands of professionals who do this for a living and have already thought about it. So rather than have you recreate the wheel, it’s better to study what’s already been done.

Uniclass

Uniclass is part of the UK-based National Building Specification (NBS) organization. It uses a hierarchical set of 12 tables:

- Activities

- Complexes

- Elements/Functions

- Entities

- Products

- Spaces/Locations

- Systems

- Roles

- CAD

- Project Management

- Tools and Equipment

- Form of Information

Clearly, some of these are more relevant for our purposes than others. Specifically, you’ll be most interested in the first seven tables. Here’s how they relate to another according to NBS:

Spaces/Locations exist in Entities which form part of a wider Complex and Activities may take place in any of these. Entities are composed of Elements/Functions, Systems and then Products.

To give an example, here’s how the Uniclass hierarchy might be used to classify roof framing:

- Systems

- 30 Roof, floor and paving systems

- 30_10 Pitched, arched and domed roof structure systems

- 30_10_30 Framed roof structure systems

- 30_10_30_25 Heavy steel roof framing systems

- 30_10_30 Framed roof structure systems

- 30_10 Pitched, arched and domed roof structure systems

- 30 Roof, floor and paving systems

UniFormat

UniFormat arranges data about the physical parts of a construction project by function, meaning what role an element plays in the overall facility or how it is used. Originally created for the US government (and later codified as the ASTM E1557 standard), UniFormat is now used by public and private entities and managed by the Construction Specifications Institute (CSI).

It’s often used at the early stage of projects as it is so intuitive and easy to use, especially when the project is still being defined. It is very closely related to, though subtly different from, UNIFORMAT and UNIFORMAT II which are more focused on government projects.

UniFormat has fewer first level groupings than some of the other construction specification standards, so we’ll share an abbreviated list of both first and second level groupings below to give you an idea of how things are arranged. We’re leaving off the Level 3 -5 elements as well as a number of Level 2 elements for clarity and brevity.

- Introduction

- 10 – Project Description

- A – Substructure

- A10 – Foundations

- B – Shell

- B10 – Superstructure

- B20 – Exterior Vertical Enclosures

- C – Interiors

- C10 – Interior Construction

- C20 – Interior Finishes

- D – Services

- D20 – Plumbing

- D30 – Heating, Ventilation, and Air Conditioning (HVAC)

- D50 – Electrical

- E – Equipment & Furnishings

- E10 – Equipment

- E20 – Furnishings

- F – Special Construction and Demolition

- F10 – Special Construction

- G – Sitework

- G10 – Sitework

- Z – General

- Z10 – General Requirements

To give an example, here’s how the UniFormat hierarchy might be used to classify metal roof framing:

- B – Shell

- B10 – Superstructure

- B1020 – Roof Construction

- B1020.10 – Roof Structural Frame

- B1020 – Roof Construction

- B10 – Superstructure

MasterFormat

MasterFormat is the most popular construction specification system in North America. It too is a product of CSI. Unlike UniFormat, it approaches classification from the perspective of materials instead of functional systems.

Prior to 2004, MasterFormat had 16 Divisions but was more recently reorganized into 50 Divisions across a few different groups. Below is an abbreviated list to give you an idea of the structure. Quite a few of the 50 total divisions have been removed for clarity and brevity:

- PROCUREMENT AND CONTRACTING REQUIREMENTS GROUP

- Division 00 — Procurement and Contracting Requirements

- SPECIFICATIONS GROUP

- General Requirements Subgroup

- Division 01 — General Requirements

- Facility Construction Subgroup

- Division 03 — Concrete

- Division 05 — Metals

- Division 08 — Openings

- Division 09 — Finishes

- Division 12 — Furnishings

- Facility Services Subgroup:

- Division 22 — Plumbing

- Division 23 — Heating, Ventilating, and Air Conditioning (HVAC)

- Division 26 — Electrical

- Site and Infrastructure Subgroup:

- Division 31 — Earthwork

- Division 33 — Utilities

- Process Equipment Subgroup:

- Division 40 — Process Interconnections

- Division 41 — Material Processing and Handling Equipment

- General Requirements Subgroup

To give an example, here’s how the MasterFormat hierarchy might be used to classify metal roof framing:

- 05 00 00 – Metals

- 05 21 00 – Steel Joist Framing

- 05 21 23 – Steel Joist Girder Framing

- 05 21 00 – Steel Joist Framing

OmniClass

OmniClass is a system of 15 tables for organizing all construction information. It is supported by CSI as well. As you can see below, Omniclass incorporates both UniFormat and MasterFormat standards, among other things.

- Table 11: Construction Entities by Function

- Table 12: Construction Entities by Form

- Table 13: Spaces by Function

- Table 14: Spaces by Form

- Table 21: Elements (Copy of UniFormat)

- Table 22: Work Results (Copy of MasterFormat)

- Table 23: Products

- Table 31: Phases

- Table 32: Services

- Table 33: Disciplines

- Table 34: Organizational Roles

- Table 35: Tools

- Table 36: Information

- Table 41: Materials

- Table 49: Properties

OmniClass, including Tables 21 and 22, can be easily downloaded from CSI above for further investigation. Given the duplication of OmniClass with both Uniformat and MasterFormat, it’s not worth discussing in further detail.

Do You Need a WBS For You Container Home Project?

So far, we’ve given you a ton of information on how building professionals use construction specification standards for a variety of purposes, including the creation of work breakdown structures. You may be thinking, “This all seems a little complex…how does this apply to me?”

Let’s start with those of you planning on a Do-It-For-Me project using a hired builder. If you’re paying a builder, and they are professionals, they should be using some type of WBS as part of their overall project management system anyway.

As a consumer though, that’s a detail that’s probably a little too down into the weeds for you to worry about. After all, you aren’t going to ask your builder what operating system he uses on the company computers; it just doesn’t matter for your purposes.

Instead, you’ll want to see a cost estimate/budget and a schedule, both of which are informed by their WBS. The quality of both of these documents will reflect the quality of the builder’s project management program. And that, in turn, will help you know if you can expect them to deliver your project on-time, within budget, and with high-quality.

Now, for those of you planning a Do-It-Yourself build, the WBS becomes much more important. Whether you’re explicitly making one or just imagining one in your brain, you’ll still be using it to create things like your project schedule and budget.

However, remember that for a DIY container project, remember that the best organizational or classification system is the one you’ll actually use. So read through our recommendations then adapt and tailor as you see fit for your specific circumstances.

With that said, most of you can probably quickly realize that some kind of system is only going to help you save money and time. So rather than have you sort through the various classification systems above, we’ve created one just for you.

Introducing the Container Home Classification System

Our Recommended WBS for container homes is the one we’ve tailor-made just for container house enthusiasts. It borrows heavily from UniFormat and UNIFORMAT II standards (remember, they are almost equivalent) but with many sections deleted and modified.

This is an intuitive classification system for people new to construction and thinking at the early stages of a container project. Check it out below:

- A Foundation

- B Shell

- B10 Superstructure

- B20 Exterior Enclosure

- B2010 Exterior Walls

- B2020 Exterior Windows

- B2030 Exterior Doors

- B30 Roofing

- C Interiors

- C10 Interior Construction

- C20 Stairs

- C30 Interior Finishes

- D Services

- D20 Plumbing

- D30 HVAC

- D40 Fire Protection

- D50 Electrical

- E Furnishings & Fixed Equipment

- G Sitework

- G10 Site Preparation

- G20 Site Improvements

- G30 Mechanical Utilities

- G40 Electrical Utilities

- Z General

- Z70 Taxes, Permits, Insurance, and Bonds

- Z90 Fees and Contingencies

To further modify the Container Home Classification System, we have a helpful resource to share. The US Navy has an online version of UNIFORMAT II with detailed descriptions for almost all elements. If you think you need more detail than what the Container Home Classification System offers, you can go here to see all possible elements.

Combining the Container Home Classification System and MasterFormat

What we’re about to share below is an advanced method that will be overkill for most people. But just in case you have a complex container project or just like being super-organized, we’re sharing it.

If you want to have more detail in your WBS, or even create a set of specifications, you can place relevant, lower-level sections of the MasterFormat system into the Container Home Classification System. Table 21 of OmniClass makes this super simple by listing out the relevant MasterFormat references that pertain to each UniFormat element (and remember the Container Home Classification System is based heavily on UniFormat so you can easily tie them together).

For instance, let’s say you’re working on the section of your WBS for the interior doors, specifically sliding doors. In UniFormat, you’d have them here:

- C Interiors

- C10 Interior Construction

- C1030 Interior Doors

- C1030.25 Interior Sliding Doors

- C1030 Interior Doors

- C10 Interior Construction

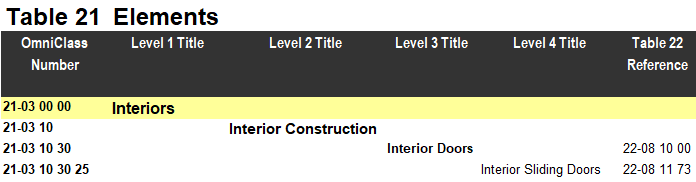

In OmniClass Table 21, you’d have them in the same place, just with slightly different numbering (‘C’ is replaced by ’03’):

- 21-03 Interiors

- 21-03 10 Interior Construction

- 21-03 10 30 Interior Doors

- 21-03 10 30 25 Interior Sliding Doors

- 21-03 10 30 Interior Doors

- 21-03 10 Interior Construction

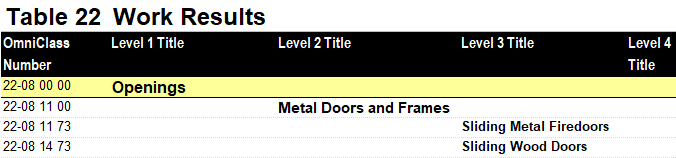

You’ll notice that the last column is called Table 22 Reference, which shows us the specific MasterFormat work result that is related to interior sliding doors! We see that generic Interior Doors have a Table 22 Reference of 22-08 10 00, while Interior Sliding Doors are at 22-08 11 73. Let’s stay with the example and focus on sliding doors.

You can see above how sliding doors are classified in Table 22 as Sliding Metal Firedoors. We also scrolled down a bit to find Sliding Wood Doors at number 22-08 14 73 too, just for grins. It’s likely that you’ll find similar products like this close by in the hierarchy. Also, remember that you can download a Microsoft Excel version of Omniclass Table 22 from the same place you downloaded Table 21, which we mentioned above.

What good does linking Table 21 (UniFormat) and Table 22 (MasterFormat) accomplish? Quite a bit actually.

Because MasterFormat is the industry standard (at least in North America) for specifying materials, many manufacturers and dealers are set up to work with these numbers. You can use a site like Arcat to see manufacturers of sliding metal doors, just by going off of the MasterFormat number. You can also get CAD drawings, specifications, and other information for particular products.

Or, if you want to see how the US Government specifies its Sliding Metal Doors, you can look up its free version of the specs for this MasterFormat number by viewing the Unified Facility Guide Specifications from the Whole Building Design Guide or the Master Construction Specifications from the Department of Veterans Affairs. This gives you an idea of how a professional designer would specific these types of products (methods of installation, product certifications, etc.) and that you might want to use as inspiration. Otherwise, you’d need to purchase specs from CSI (although if you hire an architect, they probably already have access to the CSI specs).

To reiterate, none of what we’ve covered in this last section is crucial to a small project like a shipping container building, but it just shows you how professionals in the building sciences do their job. And it may help you become better organized, find interesting products, etc.

Summary

If you had not ever heard of Work Breakdown Structures before reading this article, you definitely learned a lot! We hope we’ve made it clear that a WBS is a simple yet powerful tool.

As we mentioned, you’ve probably been making mental WBS’s all along. Our purpose here is to help you professionalize that process and learn how to get it in writing. It’s a little work on the front end that will help you throughout the duration of your project as you work to control quality, costs, and timeline.