Understanding shipping container dimensions is a prerequisite to using them for storage or even combining them into a creative container home. The multitude of shapes and sizes of storage containers (Open-top, high-cube, 48-foot, flat-rack, etc.) leads to numerous configurations available for sale.

While 40-foot standard shipping containers are what most people are familiar with, there are longer, shorter, wider, and taller options available. In order to help you find what you’re looking for faster we’ve divided this article into the following sections:

- Basics: Terminology and Dimensional Caveats

- Common Shipping Containers: Dimensions of 20ft, 40ft, and 45ft – Regular and High Cubes, Dry Cargo Containers and Reefers

- Less Common Shipping Containers: Dimensions of 48ft, 53ft, and Pallet Wide Containers

- Rare Shipping Containers: Descriptions of Half-height, Tricon, Side-Opening, etc.

Shipping Container Size Basics

Before jumping into the actual dimensions, we need to level-set and make sure you understand a few important facts about shipping containers.

Terminology

- ISO: The International Organization for Standardization creates standards for a huge number of industries and uses, including shipping containers. There are several standards relevant to containers, but ISO 668 and ISO 1496 cover the size and strength requirements relevant to our discussion here. You may see containers referred to as ‘ISO Boxes’, ‘ISO Shipping Containers’, etc. This just means that the container in question conforms to the ISO requirements and isn’t a non-standard container.

- Intermodal: This just means that a container can be used on multiple types of transportation infrastructure, such as rail and truck in addition to the various sizes of container ships. All ISO standard containers with the familiar corner castings are intermodal shipping containers too.

- CONEX: Conex (sometimes spelled connex) is an abbreviation for container express, a name for the overall shipping system enabled by containers when they were invented several decades ago (read our article about shipping container history for more information). A ‘conex box’ is just another name for a shipping container.

- High Cube: A shipping container that is one foot taller than a regular container.

- TEU: Twenty-foot equivalent unit. When talking about things like container ship capacity, the sizes of smaller containers, etc. the unit of measure is a TEU. One 20ft container is a TEU, while a 40ft container is two TEUs.

- General Purpose (Dry Storage): The typical shipping container you are used to seeing and what is normally used for container construction. This is in comparison to tank containers (for liquids), bulk storage containers (for particulates like grain), and flat rack containers (for large objects that won’t fit in a regular container.

- Tare Weight (Empty): The weight of an empty shipping container.

- Max Load Capacity (Net): The maximum weight or payload that can be safely carried in a container. May be called the net weight, as it is the difference (net) of the Maximum Gross Weight minus the Tare Weight. This max load must be distributed fairly evenly across the entire floor area of a container. Small but especially heavy items may require additional workarounds.

- Maximum Gross Weight (MGW): The maximum weight of a fully loaded container. This is the sum of the Tare Weight and the Max Load Capacity.

Technicalities

- Volume: We’ve given interior and exterior measurements of containers below, but not volume as it feels a bit redundant. If you’re looking for the volume or cubic capacity of a container, just multiply the length, width, and height together to get either cubic feet or cubic meters.

- Non-Standard Containers: Most of the containers we share here are either built to ISO standards or at least some other international standard of uniformity and performance. However, there are also factories that make boxes that look like shipping containers yet have different sizes and strengths. For instance, if you see a 10ft or 12ft wide steel box, it may sound great for a wider room width, but you’re giving up a lot of other capabilities potentially, and it’s definitely a buyer beware situation.

Caveats

- Dimensional Accuracy: The ISO Standards governing shipping container sizes typically specify the minimum or maximum values for a particular dimension. This effectively means there can be some variability in the dimensions of shipping containers that are the same nominal size and type. In most cases, the differences are no larger than ½ inch or so, which is pretty small given the large size of a container. However, reefer or refrigerated shipping containers have more variability in their dimensions as they are not all designed for the same temperature requirements and thus have different amounts of insulation. In general, exterior dimensions are less variable as ultimately all containers need to be able to attach together. Also, note that there are some oddly-sized containers that are not made to ISO container dimension standards.

- Weight Accuracy: Another area of variability is in the weights. For instance, some container manufacturers choose to exceed the minimum required strength, and in doing so their ISO containers may weigh more to account for additional materials. With that in mind, you may come across containers with differences in gross, tare, or payload weights that differ by hundreds or even thousands of pounds. As we discussed above, the ISO requires minimums for strength, but manufacturers can exceed it.

- Door Height: The height of the container cargo doors is generally less than the interior height because of the door header, a piece of steel that spans across the top of the door opening and adds strength to the container. It’s kind of like walking through a doorway in a regular house: right above the door is a little shorter, but the rest of the room has a higher ceiling.

- Refrigerated Container Length: Refrigerated containers usually have about two feet of their length dedicated to holding the refrigeration equipment that keeps them cool. For this reason, their interior length is about two feet shorter than you would otherwise expect.

A good understanding of these basics will clarify the opportunities that come with shipping containers, help you speak a common language with suppliers and building professionals, and ensure you understand exactly what you need to achieve your goals.

As you’ll see below, there are MANY possible container configurations. We can’t cover every option, so we’ll focus on the most commonly used shipping containers.

For each container we feature, we’ll highlight the exterior dimensions, interior dimensions, cargo door sizes, and weights. And, we’ll always provide both US units and metric shipping container dimensions for our readers around the world.

Finally, if you’re looking for the specifications of the small components that make up containers (like the corner fittings, corrugated steel panels, etc.), head over to our article Shipping Container Standards, Components, and Classifications.

Common Types of Containers

We start off with the most common varieties of shipping containers. These are the containers you’re most likely to see out ‘in the wild’ and for sale. Although they fill a few different roles and sizes, they are all the water-tight, dry containers you know and love.

Generally, these shipping containers are quite versatile and can be used for a wide variety of applications. Most transportation infrastructure is designed with these in mind first, and compatibility with more obscure types may occasionally be lacking.

This versatility and compatibility are probably what made these common shipping containers so popular in the first place. An understanding of these common variants of sea containers will form a solid foundational knowledge for you to build on: literally and figuratively.

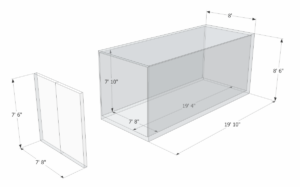

20 foot Container Dimensions (20′ std)

The standard 20ft shipping container, known as a General Purpose (GP) container is popular due to its ease of maneuverability and lower weight. There are some people that make tiny cabins out of a single 20ft container, but more often than not, they are used as part of a larger build.

While 20ft containers are overall cheaper than their corresponding 40ft alternatives, their price per square foot is actually more expensive. For the size of the same building, you’d need twice as many 20ft containers as 40ft ones. So you’d be saving money on each container while actually spending more in terms of overall project costs.

So unless your design actually requires 20ft containers, using 40ft boxes is usually a better way to get more floor space.

You’ll sometimes see cargo ship capacity or trade volumes stated in TEUs. This stands for twenty-foot equivalent units and just means the volume of freight that could fit in containers just like this.

- External Measurements: 19ft 10in long; 8ft wide; 8ft 6in high [6.05m long; 2.44m wide; 2.59m high]

- Internal Measurements: 19ft 4in long; 7ft 8in wide; 7ft 10in high [5.90m long; 2.35m wide; 2.39m high]

- Door Opening Measurements: 7ft 8in wide; 7ft 6in high [2.34m wide; 2.29m high]

- Weights: 4,960 lbs tare; 62,240 lbs max load [2,250 kg tare; 28,230 kg max load]

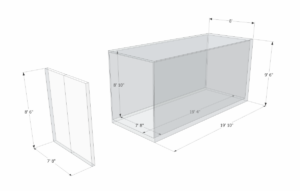

20 foot High Cube Container Dimensions (20′ HC)

20ft high cube shipping containers are similar to standard 20ft shipping containers but with the added room of an additional 12 inches of height. This makes it easier to have interior insulation and light fixtures while still maintaining a normal ceiling height. It also opens up your whole design, and oftentimes higher ceilings will help to make the entire interior feel much larger overall.

- External Measurements: 19ft 10in long; 8ft wide; 9ft 6in high [6.05m long; 2.44m wide; 2.89m high]

- Internal Measurements: 19ft 4in long; 7ft 8in wide; 8ft 10in high [5.90m long; 2.35m wide; 2.70m high]

- Door Opening Measurements: 7ft 8in wide; 8ft 6in high [2.34m wide; 2.59m high]

- Weights: 5,070 lbs tare; 62,130 lbs max load [2,300 kg tare; 28,180 kg max load]

20 foot Refrigerated Container Dimensions (20′ reefer)

Sometimes known as a reefer container, the 20ft refrigerated shipping container is a regular 20ft container with the added benefit of insulation. If you’re planning to insulate anyway, this could be a shortcut depending on some of your other design choices. We’ve written an article on the things to think about with refrigerated containers to help you.

In another article, we spoke about how insulation is usually integral to keeping your home at a comfortable temperature. Unless you live in a ‘perfect’ climate, insulation will probably be necessary. Therefore, if you can find a good deal and work around the tradeoffs, a refrigerated container might be a great way to save some money by eliminating the work of insulating the shipping container yourself.

- External Measurements: 19ft 10in long; 8ft wide; 8ft 6in high [6.05m long; 2.44m wide; 2.59m high]

- Internal Measurements: 17ft 10in long; 7ft 6in wide; 7ft 5in high [5.44m long; 2.28m wide; 2.26m high]

- Door Opening Measurements: 7ft 6in wide; 7ft 5in high [2.28m wide; 2.26m high]

- Weights: 6,400 lbs tare; 60,800 lbs max load [2,905 kg tare; 27,575 kg max load]

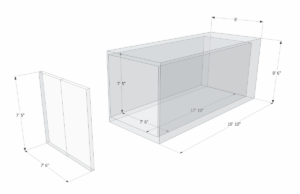

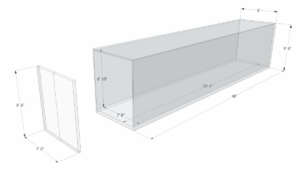

40 foot Container Dimensions (40′ std)

If you’re curious about the size of the average shipping container, this is it! A 40ft shipping container is the most common container you will find. They are big enough to allow sectioning them off multiple rooms (for example, a one-bedroom home) but they can also be combined into a home of any size. Like the general-purpose 20-foot shipping containers, their lower ceiling height could be an issue for those that want interior insulation while still having a reasonable ceiling height.

When your design calls for more than one 20ft container, it’s worth taking a closer look at your requirements. You may be able to achieve the same goals by buying 40-ft containers instead and subdividing them up into two spaces.

If you’re ok with narrow rooms, 40′ container dimensions will certainly support a smaller container home or cabin. There are studio apartments in large cities that are about this size, and while cozy, it’s liveable if you don’t have a lot of ‘stuff’. This is why they are such a popular choice in the container architecture world.

- External Measurements: 40ft long; 8ft wide; 8ft 6in high [12.19m long; 2.44m wide; 2.59m high]

- Internal Measurements: 39ft 6in long; 7ft 8in wide; 7ft 10in high [12.04m long; 2.35m wide; 2.39m high]

- Door Opening Measurements: 7ft 8in wide; 7ft 6in high [2.34m wide; 2.29m high]

- Weights: 8,333 lbs tare; 58,863 lbs max load [3,780 kg tare; 27,600 kg max load]

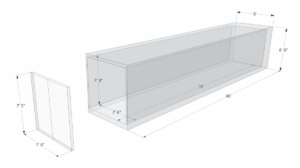

40 foot High Cube Container Dimensions (40′ HC)

If you like the size of a 40ft container but need a bit more vertical space, a 40 ft high cube container offers you the same floor area with an additional one foot of overhead room. This gives you the extra volume for insulation, wiring, and fixtures while still being able to have a normal interior ceiling height in a container home.

One extra foot of vertical space may not sound like much, but with container homes, it can make a big difference. Not only will the rooms feel better, they actually are bigger and thus more capable of holding your possessions.

- External Measurements: 40ft long; 8ft wide; 9ft 6in high [12.19m long; 2.44m wide; 2.89m high]

- Internal Measurements: 39ft 6in long; 7ft 8in wide; 8ft 10in high [12.04m long; 2.35m wide; 2.70m high]

- Door Opening Measurements: 7ft 8in wide; 8ft 6in high [2.34m wide; 2.59m high]

- Weights: 8,750 lbs tare; 58,450 lbs max load [3,968 kg tare; 26,512 kg max load]

40 foot Refrigerated Container Dimensions (40′ reefer)

With a 40ft refrigerated or reefer container, you get the benefits of the 40ft shipping container capacity along with built-in insulation. However, in most cases, this also includes an industrial refrigeration unit that you’ll want to get rid of, and you’ll have to patch over the hole it leaves. For this reason and others, you should learn more about the pros and cons of building with refrigerated containers.

- External Measurements: 40ft long; 8ft wide; 8ft 6in high [12.19m long; 2.44m wide; 2.59m high]

- Internal Measurements: 38ft long; 7ft 6in wide; 7ft 5in high [11.58m long; 2.28m wide; 2.26m high]

- Door Opening Measurements: 7ft 6in wide; 7ft 5in high [2.28m wide; 2.26m high]

- Weights: 10,780 lbs tare; 56,420 lbs max load [4,900 kg tare; 25,645 kg max load]

40 foot Refrigerated High Cube Container Dimensions (40′ HC reefer)

If you love the size of a 40ft container and the included insulation of a refrigerated container, but you want a bit more headroom, a 40ft refrigerated high cube container might be the right choice. It won’t offer you the ability to easily embed your wires behind the ceiling like you could with a regular container where you add insulation later. But if you like an industrial look with surface-mounted conduit and high loft-esque ceilings it could be a great fit.

These refrigerated high cube shipping containers are a quick passport to a roomy, temperate living space with the least amount of work. It goes to show that you don’t always have to sacrifice space and open-concept design when you are building with storage containers.

- External Measurements: 40ft long; 8ft wide; 9ft 6in high [12.19m long; 2.44m wide; 2.89m high]

- Internal Measurements: 38ft long; 7ft 6in wide; 8ft 5in high [11.58m long; 2.28m wide; 2.57m high]

- Door Opening Measurements: 7ft 6in wide; 8ft 5in high [2.28m wide; 2.57m high]

- Weights: 10,490 lbs tare; 64,470 lbs max load [4,760 kg tare; 29,240 kg max load]

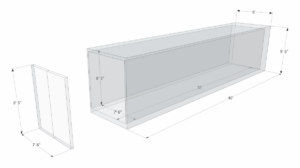

45 foot High Cube Container (45′ HC)

The 45-foot containers are a bit different than what we’ve previously discussed. They have the normal container corner castings 40 ft apart, but then they have two equal ~2.5ft extensions on each end of the container. These extensions also have corner castings at the actual corner extents of the container. Having multiple sets of corner castings allows 45ft containers to be stacked with 40ft containers.

Most 45ft containers you see are high-cubes with the additional benefits that an extra foot of room height brings. Thanks to their added five feet of length, 45-foot containers allow you to have a container home with slightly bigger rooms. It’s even possible to make a two-bedroom unit if you can be space-efficient.

- External Measurements: 45ft long; 8ft wide; 9ft 6in high [13.72m long; 2.44m wide; 2.89m high]

- Internal Measurements: 44ft 6in long; 7ft 8in wide; 8ft 10in high [13.56m long; 2.35m wide; 2.70m high]

- Door Opening Measurements: 7ft 8in wide; 8ft 6in high [2.34m wide; 2.59m high]

- Weights: 10,580 lbs tare; 56,620 lbs max load [4,800 kg tare; 30,480 kg max load]

Less Common Containers

The shipping containers in this group are certainly less common than those above but are still fairly widely available in certain regions as we explain below. It might also be more difficult to integrate them into your design due to their slightly irregular sizing, but they can be just perfect for more specific needs.

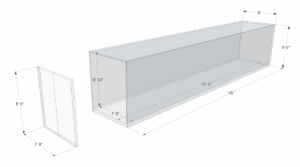

48 foot High Cube Container Dimensions (48′ HC)

A 48ft container is the first container we’ll discuss that has a different width than all containers previously mentioned. With an additional 6in of width, a 48ft container is 6.25% wider than a 40ft or 45ft container. It doesn’t sound like much, but this extra width gives you just a bit more breathing room for insulation while not feeling like your rooms are too narrow. Most 48ft containers are also high cubes, so they have an extra 12in of height as well.

Much like 45ft containers, 48ft shipping containers have multiple sets of container corner castings: one set at the actual corners, and one set 40ft apart. This enables it to be stacked with 40ft containers. The two ~4ft extensions on each of the 48ft shipping containers are similar in design to those of the 45ft container, just a bit longer.

With an additional 8ft of length and 6in of width, a 48ft shipping container makes having a second bedroom or just bigger other rooms possible. The ~4ft extensions on each end are also possible candidates for cantilevered areas on the upper floors.

- External Measurements: 48ft long; 8ft 6in wide; 9ft 6in high [14.63m long; 2.59m wide; 2.89m high]

- Internal Measurements: 47ft 6in long; 8ft 2in wide; 8ft 10in high [14.48m long; 2.49m wide; 2.70m high]

- Door Opening Measurements: 8ft 2in wide; 8ft 6in high [2.49m wide; 2.59m high]

- Weights: 10,920 lbs tare; 56,280 lbs max load [4,953 kg tare; 25,527 kg max load]

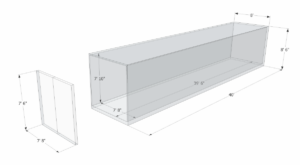

53 foot High Cube Container Dimensions (53′ HC)

The 53ft container is the largest mass-produced container that you’re likely to ever see. Like a 48ft container, it is also 6in wide than a 40ft container and a foot higher seeing as it’s a high cube. And like a 48ft container, a 53ft container has corner castings at 40ft, followed by two equal extensions that bring the length out to 53ft. However, the extensions on a 53ft container are about 6.5ft long each.

If you want to build something using only a single container, a 53ft container gives you the largest possible interior volume. However, depending on where you’re located, it may be cheaper to buy multiple, small containers instead of one large 53ft container. More importantly, 53ft containers have limited availability and are predominantly used in North America.

Initially, 53-foot containers weren’t built strong enough for ocean travel, as they were only intended for domestic shipments in the United States. However, some companies eventually created reinforced 53-footers that were up to the task of ocean voyages. It’s something to keep in mind when you’re shopping if you’re thinking about structurally taxing designs like bridging.

The ISO standards don’t really address 53-foot containers since they are not really a worldwide standard. However, the Association of American Railroads (AAR) does provide standards for 53-foot containers in their Manual of Standards and Recommended Practices: Section I (Intermodal Equipment Manual). This document includes standards and guidelines including ‘Standard M-930 Containers for Domestic Intermodal Service‘.

As you can see from these larger 48ft and 53ft containers, you don’t always have to make as many sacrifices as you think when building with containers. There is a tendency to believe that container homes are cramped and bare, but that doesn’t have to be the case! With some creative usage of these massive high-cube containers, you can build a home that has all the size you desire while letting your creativity shine.

- External Measurements: 53ft long; 8ft 6in wide; 9ft 6in high [16.15m long; 2.59m wide; 2.89m high]

- Internal Measurements: 52ft 6in long; 8ft 2in wide; 8ft 10in high [16m long; 2.49m wide; 2.70m high]

- Door Opening Measurements: 8ft 2in wide; 8ft 6in high [2.49m wide; 2.59m high]

- Weights: 11,070 lbs tare; 56,130 lbs max load [5,020 kg tare; 25,460 kg max load]

40 foot Pallet Wide High Cube Container Dimensions (40′ PW HC)

Pallet wide containers are just a bit wider (roughly 2in) than regular width containers but not as wide as 48ft and 53ft containers. The extra width is to accommodate ‘euro pallets’.

Standard pallets in the United States and some other countries are 48in (1219mm) by 40in (1016mm). In contrast, Euro pallets are 800mm (2ft 7.5in) by 1200mm (3ft 11.2in). The slightly wider size of a pallet-wide 40ft container allows it to hold 30 euro pallets, while a regular 40ft container can only hold 25.

If you aren’t planning to store euro pallets, this extra width just gives you a tiny bit more space for your interior walls, insulation, etc. Whether it’s worth paying extra for this small bit of additional width really depends on your design. But for people, if you’re going to pay extra, you might as well go for a longer 48ft container where you also get six more inches of width.

You’re most likely to find pallet wide containers in Europe, where euro pallets are prevalent. But they may pop up in other locations as well that trade with Europe.

- External Measurements: 40ft long; 8ft 2in wide; 9ft 6in high [12.19m long; 2.49m wide; 2.89m high]

- Internal Measurements: 39ft 6in long; 8ft wide; 8ft 10in high [12.04m long; 2.44m wide; 2.70m high]

- Door Opening Measurements: 8ft wide; 8ft 6in high [2.44m wide; 2.59m high]

- Weights: 8,636 lbs tare; 63,015 lbs max load [3,917 kg tare; 28,583 kg max load]

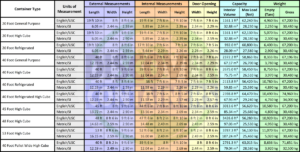

Common Shipping Container Size Chart

We’ve covered a lot of information about the sizes and dimensions of the most common shipping containers, but it’s spread throughout the text of this article. You’ll be happy to know that we also have a container size chart that consolidates most of the pertinent information in one place.

So if you’re looking for the dimensions, weights, and capacities of common shipping containers in the form of a table, we have you covered! Just click the table for a larger version that’s actually readable.

As we’ve said in other parts of this article, be aware that most of these container sizes are not chiseled in stone. Different manufacturers can alter some of the dimensions, and more often the weights and capacities, of their containers. So be sure to field measure or get a manufacturer data sheet before making big decisions regarding any container projects.

Rare Shipping Containers

The below shipping containers are fairly rare but we’ll still acknowledge their existence in case you happen to stumble across one. Understand that this is not a 100% complete list of every possible variety of shipping containers in the world.

Rare Container Sizes

- Different length pallet-wide containers, like 20ft and 45ft long pallet wides

- Half-height containers, which are half as tall as normal containers, and come in various lengths

- Super high cube containers are 2ft taller than a regular container and 1ft taller than a high cube and come in various lengths and widths

- Slightly shorter containers that are 8ft tall instead of 8ft 6in tall

- Short containers used by US and Allied militaries

- 5ft long (Call a Quadcon, as it takes four to make a TEU)

- 6ft 5.5in long (Called a Tricon, as it takes three to make a TEU)

- 10ft long (Called a Bicon, as it takes two to make a TEU)

- Purpose-built containers that are created specifically for non-cargo carrying reasons like houses, etc. We’re seeing these ‘container-like’ boxes more and more from China, and while they are often larger than regular containers, they don’t meet any of the same certifications for strength and durability.

Rare Container Types

- Flat-pack containers are containers that literally fold flat when not in use. These aren’t normally used for freight transport but rather are a way of moving several containers in the space of one regular container. In exchange for being able to fold, flat-pack containers are typically much less strong than other containers. Most flat-pack containers don’t meet ISO standards, and we don’t recommend their use for anything other than basic storage.

- Open Top containers that don’t have a metal roof and allow cargo that may protrude slightly above the roofline of the container. An open-top container also permits easier loading for certain types of cargo. If you’re planning to add a loft and build another roof, these containers will save you from having to cut out the container’s roof.

- Removable Top containers have a hard, metal roof similar to a standard container, but it is removable for loading heavy or oversized shipping container cargo that is easier to insert vertically through the roof.

- Double-Ended Containers (Sometimes called Tunnels) have container doors on both ends, instead of just on a single end like with standard containers.

- Side-opening containers have two sets of bi-folding doors on one of the long sides of the container, permitting unrestricted side access. These containers can be good for people who want to secure their container storage when they are gone but have open sides with lots of glass when the doors are open.

- Tank containers are used to store liquids and are usually cylindrical tanks surrounded by the familiar rectangular shape of a traditional container frame. These containers are not really useful for construction purposes.

- Dry bulk containers look similar to general-purpose containers, but they usually have inlets on the roof and outlets in the lower part of the door. These containers are used to store grain and other particulate materials so that they can be poured out at their destination.

- Insulated containers have insulation that’s similar to a refrigerated container but without the actual refrigeration equipment. For most container home builders, this is actually preferred, as you most likely wouldn’t use the refrigeration equipment anyway.

Rare Container Materials

- Steel floor containers are lighter and stronger than traditional wood flooring containers while also being easier to clean. They also don’t have any pesticides used on the floor.

- Bamboo floor containers look similar to the plywood of traditional containers but use bamboo as the source material instead of trees. Bamboo is a bit more pest-resistant than wood and it is much more renewable (Bamboo can be harvested in sometimes as little as 4-5 years, while trees need to grow for decades).

- Aluminum Shipping Containers are built of non-ferrous, non-magnetic, and non-rusting aluminum. Since aluminum is less strong than steel by volume, the structural components are less strong in aluminum containers.

Summary

Now that we have given you a ton of new information on different shipping container sizes, functions, specifications, and designs, you might be wondering what to do with all the data and details we shared.

Our number one tip is to simply familiarize yourself with the wide array of cargo container options. And the shipping container sizes chart we provided earlier in the article is a good way to start to do that.

You need to be aware of the shipping containers that are available to you, and we mean that in two ways. First is knowing what shipping containers are actually being manufactured in the world. And second, you must determine which shipping containers can be economically sourced in your geographic area.

A big takeaway from this article is understanding that your location has a large effect on the availability of different types and sizes of containers. Just because someone, somewhere manufactures a certain size and type of shipping container doesn’t mean you can actually find any close to where you live. If you can’t, you may need to hire someone to ship your container unless the seller can do it for you.

Once again, remember that the ISO grants a bit of tolerance on the measurements they specify. And, some other measurements are up to the manufacturer. If you need to know a near-exact dimension, it would be best to field measure it on the actual containers you purchase.

35 Responses

I have a customer that would like to stack containers in the same orientation, but the containers would be of varying lengths and widths…

If you stack an 8′-6″ wide container on top of a 8′-0″ wide container (or vice versa) is that problematic? (that the corner point loads would not align, and the corner point load would be cantilevered beyond the container below it? (or vice versa – the point load would fall on the railing below it and not on the corner post?)

Also when you stacking two containers of different lengths (53′ on 40′)… are they supposed to be centered on one another because of the extension on each side… (i.e. 40′ typical, with 6.5′ cantilever/ extension each side), or can it just cantilever out on one side (i.e. 40′ with 13′ cantilever/ extension on one side)?

(question regarding container framing (post locations) – not how far something can cantilever…)

Thank you

As one of the pictures in the article shows, the intermediate fittings (The places on a longer/wider container like a 48 or 53 footer where the corners would normally be on a 40ft container) should have different shapes to them than regular corner fittings. This is so that they can mate to the normal 40 ft corner fitting placements. All containers are typically supposed to have an equal center to center transverse measurement of the aperture (hole) on these fittings, regardless of container size. In other words, there should be a match of corner fittings such that you could use twist locks between stacked containers of different sizes. But to answer your second question, yes they need to be centered, so the cantilever is split evenly on both ends.

I have a query regarding the refrigerated containers. Can they be altered to maintain at any chosen temperature? Are there any restrictions to utilizing one? Codes? Special permits? Anything specific that would rank it the lowest on cost~time compared to other alternatives i.e. outfitting a separate container or burying one. I am designing my own home, along with smaller”vacay”starter homes for each of my 4 children. Mine of course being the main, with theirs to expand at their convenience. My hopes are to reduce our carbon footprint, teach environmental responsibility, self-reliance, and essential survival skills (horiculture, farming, trapping, canning) I will probably annoy you with future questions but hopefully some of my dreams will inspire others to believe their dreams can become their reality, just not overnight.

We’d recommend you read our article about refrigerated containers here: https://www.discovercontainers.com/should-you-use-a-refrigerated-shipping-container-for-your-container-home/

Most people aren’t able to continue using the refrigeration unit, and supply their own HVAC unit that takes advantage of the insulation in the container.

We’d also recommend you read this article that should answer some of your questions about codes and permits: https://www.discovercontainers.com/shipping-container-zoning-permits-and-building-codes-which-states-allow-them/

Choosing between a normal container and a refrigerated one is a complex decision that is based on how cheap you can get one, how much time you have, what your intended design is, etc. You can see examples of people who used both in our Case Studies section here: https://www.discovercontainers.com/case-studies/

Note we strongly discourage burying your container, as described in Myth #3 here: https://www.discovercontainers.com/7-myths-about-shipping-container-homes-debunked/

Hi, I just wanted to know, can we able to manufacture 60 feet container. If so, I also need to know – How the base frames and top frames are designed.

Thank you

That isn’t a normal size for a container, although there may be a manufacturer out there who can produce it for you as a custom size. Perhaps more difficult would be finding a shipping company would could transport it, as the infrastructure is not designed to carry containers that long.

I’m considering using a 40 ft container as a bridge/tunnel to cross a 10 ft wide wet weather creek. Are you aware of anyone using them this way? My primary concern is how much loads in the center of the 10 ft span.

We haven’t really seen anyone doing this, but it’s certainly possible. Given the narrow width, a container isn’t a great solution for a bridge for a car…you’d have to drive really slowly through it to avoid hitting the sides. But if you’re talking about a man-bridge, that would make sense.

A 40-foot container is designed to support about 60,000 pounds evenly distributed on the floor. And containers are already designed to be supported at just the four corners. When they are stacked up on ships they are effectively bridges already, and the middles of the containers don’t touch each other top to bottom.

As long as you aren’t planning to carry extremely heavy loads across the bridge, it will likely meet your needs. Obviously, any modifications to the containers like cutting out the sides for windows, etc. will reduce it’s carrying capacity.

How much weight can the container carry on its roof

Regards

Mostafa

We don’t have an exact number, but in general, the roof is not designed to support any significant load. Shipping container roofs only serve to keep out the elements, but all loads are carried by the floor (then transmitted to the container below via the corner columns). If you have to get on the roof to paint, you’ll be ok. If you’re planning to turn your roof into a deck, make it into a green roof, or anything else, you’ll need to make structural enhancements.

Okay, you ROCK. Thank you very much for the measurement information.

I am wanting to cut out the ent entire side panel of my high cube 40ft container and use winches to lower the panel and then lift the panel back up when I want to lock it or move it. Could you give me some guidance on how much the side wall weighs.??

Thanks

Glen

The side walls of most containers are 1.6mm thick. You can calculate the weight of just the corrugated paneling (without the structural beams) by multiplying the density of steel (around 8g/cm3) by the volume of steel in the wall (1.6mm x 2.89m x 12.2m) x (~150% to account for the added material in the corrugation profile). This is approximately 680kg or 1500lbs.

Hi Tom I have a 40ft high cubic container. I want to use it as extra entertainment space. I’m having a very hard time finding people that have worked on shipping containers. I appreciate all the information you are providing because it helps me do some of the work my self. Do you have info on anyone in Oklahoma city yet? Thanks

Sharlo

Sharlo, get in touch via our contact page, and we can try to point you in the right direction: https://www.discovercontainers.com/contact-us/

Is there any public build videos on doing the installation of container exterior weather proofing? Was wondering if tack welding steel 2×4 studs to outside and using that for a framework to apply a closed cell foam would provide a satisfactory method to keep the desert heat from making a container an oven.

We don’t know of any specific videos off-hand, but there may be some out there. Tack welding metal studs to the exterior of a container would provide a good structural support for the spray foam insulation, but it introduces thermal bridging. You want to reduce any penetrations, and certainly any metal-to-metal contact as much as possible between the inside and outside of the building. Ideas include adhesively fastening the studs, using wooden studs, etc. If you do weld them, keep them spaced as far apart as your exterior sheathing will allow.

Hi I would like to.build courtyard container home with eight 40 ft high cube container two right behind each other for more width. With floor ceiling glass windows NB and doors that open out to courtyard from eve room. Will the windows compromise the strength of the structure

Kathleen, yes anytime you cut out a portion of the steel container, the structural integrity is affected. Whether you need additional support, and how much, is very specific to your design, so we recommend consulting with a structural engineer in your area who can provide further guidance.

Do you have to weld units you stack 2 containers on top of each other, or can they be bolted at the ends?

Welds are generally used as they provide a stronger hold; however, they can be bolted if necessary.

Hi Tom, when welding, do they have to be welded both sides, inside and out or welded outside is more than enough. Also how you would weld it underneath?

Thanks, Nik

Assuming you’re talking about connecting two containers together, we recommend welding both around the periphery of the cutout section (what you refer to as inside) and also at the corners/edges of the container (what you refer to as outside). You don’t necessarily need a continuous weld bead in both places, but you want enough welded to prevent any movement or flexing between the two pieces. You also want to ensure adequate sealing after welding to prevent moisture intrusion. As far as underneath, you’ll need to lift the containers if they are not already elevated on piles. If you choose to lift them with a jack, forklift, or other method, ENSURE you use solid pieces of material as ‘jack stands’ to hold the containers in case the jacks fail while you are underneath!

I’m trying to plan out a house made of shipping containers and I have a quick question:

Are there any smaller containers out there or is there a way to cut one and reinforce one? What is the best option?

Hi Kaylie,

The smallest mainstream containers are the 20 foot ones. Anything smaller than that is very hard to find, or you’d have to cut a longer one.

I think I read that you can get containers with one side removed, is that correct? If so, wouldn’t that be the best purchase for joining two containers together rather than cutting?

Hi Patrick,

Yes that is correct- they are known as side doors.

It depends on the price- in our experience, they are much more expensive and it’s cheaper to do the work yourself…

Hi Tom,

Im doing a project by using 20′ containers and stacking them into 7x5x3 ((LxWxH), removing almost of the side panels to create a large space for 3 storey motorcycle parking building. Have you seen the similar treatment to these containers like that by stacking them horizontal & vertically that lot, and no reinforcement structure added. is that possible? how do you think? you could imagine the center containers would had no both side, front and rear panels.

Thanks ^^

Hi Mas,

We haven’t seen an exact layout like this before, but it can certainly be done. However, it probably isn’t possible without reinforcing if you’re going to remove all the side panels.

Send us an email with any diagrams you have and we can go through it.

Can I take an open top 20′ and place it upside down on an open top 40′? This would give me 20′ double height and 20′ regular open top (no roof). If welded together, would it be structurally sound? As long a mfg is same, width should be same, will doors still open if upside down?

That’s an interesting concept. I’d like to see what you learn. I have been speaking with a container broker about also using open frame boxes to extend or elevate containers and tank containers for water reclaimation and storage. Question is how do you find ones that were used for food grade transport and not toxics. Still these are pretty rare and costly, stay in service longer. I wanted to recycle all grey water to irrigation use.

You don’t mention 53′ containers, why?

Hi Sean,

53 foot containers aren’t very common, but we may add some of these less common sizes in a future update.

Hi Tom,

If I buy a 40ft High Cube Container, cut it in half to make two 20ft High Cube Container, reinforce the cut side with steel bars and stack them 3 storeys high, will the structure strength compromised?

Thanks

Hi Wawee,

Yes, cutting the containers in half will have an impact on the structural integrity.

We recommend purchasing 20ft containers and save the time and effort…and probably money.